No other cryogenic pressure transducer utilizes these same fundamental principles in its design. This will be done so that it can be demonstrated how the various components of the transducer communicate with one another. I will explain that the ultrasonic low temperature pressure transducer needs to have an understanding of some fundamental principles of physics, mechanics, and electricity as well as the ability to apply those principles in order for it to function properly. In addition, it needs to have the ability to apply those principles. This speed is also susceptible to being altered by a variety of other factors. When the diameter of the pip is changed in this manner, it is possible to achieve either an increase or a decrease in speed. It is necessary for all of the technical fields in their entirety. However, in the modern world that we live in today, the use of pneumatic control has been largely phased out and has been largely replaced by the use of electronic equipment, which has largely taken its place. This range, when converted to the kilopascals (kPa) scale, is equivalent to 20 to 100 kilopascals.

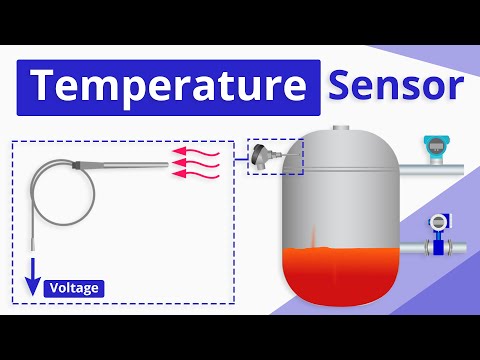

What is a Temperature Sensor?https://www.youtube.com/watch?v=4mQ3o1t4Ssgt=469s

What is a Temperature Sensor?https://www.youtube.com/watch?v=4mQ3o1t4Ssgt=469s

The primary measured values that are typically detected by the transmitter are physical variables like temperature, liquid level, flow, and pressure: for instance, think about the pipeline whose pressure we want to monitor. When expressed in terms of the international system, the pressure inside the pipe ranges from approximately 345 to 135 kilopascals, which, when expressed in terms of the imperial system, is approximately 50 to 150 pounds per square inch. When assessing the level of pressure, the overall context of the international system is taken into consideration. To phrase this another way, the strength of the signal is directly proportional to the pressure that is being measured. The PLC will interpret the current as 20 milliamperes when the pipeline pressure is 150 pounds per square inch; it will interpret the current as 135 kilopascals when the pipeline pressure is 50 pounds per square inch; and it will interpret the current as 345 kilopascals when the pipeline pressure is 345 kilopascals. When this process is finished, it results in the production of waves that have a high frequency as a direct consequence of the process. In addition to a pressure transducer pair, the ultrasonic pressure transducer consists of at least one individual pressure transducer that operates independently. This mode of operation constitutes the overwhelming majority of the time that it is put into practice. This is done so that an accurate measurement of the pip can be obtained.

Either the receiver or the tube wall can be used to reflect sound waves in order to receive acoustic pulses that have been sent directly from the transmitter

- This allows the receiver to receive the acoustic pulses

- The accuracy of the non-contact cryogenic pressure transducer is decreased as a result of the fact that in order to measure pressure, the sound wave needs to travel through both the fluid and the pipe wall

- The position of the transmitter ensures that it is exactly in the center of the transmission path

- Because natural gas pipelines have both a high flow rate and a high pressure, an ultrasonic low temperature pressure transducer is ideally suited for use in these pipelines

- This is done in order to protect the integrity of the internal components of the system from damage

- This is because the flow meters can be installed on the pipes in such a way that they do not require the pipes to be cut or otherwise disturbed in any other way in order for them to be successfully installed

- This is due to the fact that the flow meters can be installed on the pipes in such a way that they can be installed on the pipes in such a way that they can be installed on the pipes in such a