Introduction

In industries where accuracy and quality control are paramount, measuring the thickness of materials is crucial. A Wall Thickness Gauge is an essential tool used across various sectors, including manufacturing, aerospace, automotive, and construction. This blog explores how these devices work, their types, applications, and key considerations when choosing one.

What is a Wall Thickness Gauge?

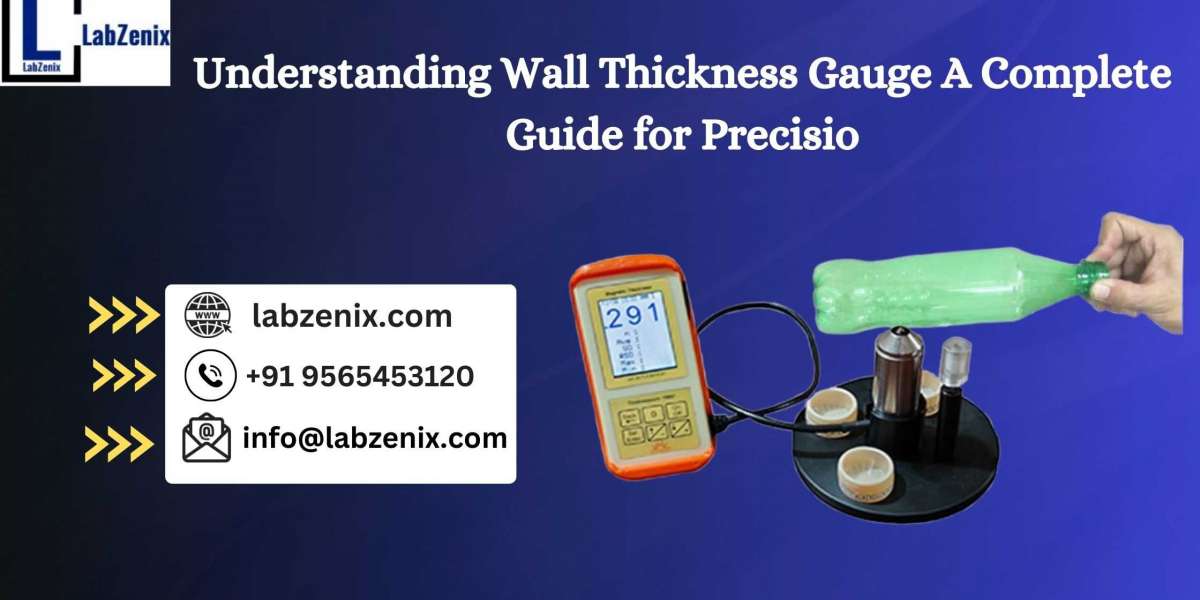

A Wall Thickness Gauge is a specialized measuring instrument designed to determine the thickness of walls in pipes, tanks, and structural materials without damaging them. These gauges utilize ultrasonic, magnetic, or mechanical principles to provide precise measurements, ensuring structural integrity and compliance with industry standards.

Types of Wall Thickness Gauges

Ultrasonic Wall Thickness Gauge: Uses high-frequency sound waves to measure thickness. Ideal for metals, plastics, and composites.

Magnetic Wall Thickness Gauge: Utilizes a magnetic field to measure thickness in non-ferrous materials like aluminum and plastics.

Mechanical Wall Thickness Gauge: A contact-based gauge typically used for soft materials such as rubber and paper.

Applications of Wall Thickness Gauges

Manufacturing: Ensures consistency in material thickness, reducing waste and improving product quality.

Oil Gas Industry: Measures pipeline walls to prevent leaks and structural failures.

Aerospace Automotive: Assists in maintaining safety standards by checking material integrity.

Construction Infrastructure: Verifies the thickness of building materials for durability and compliance.

Key Considerations When Choosing a Wall Thickness Gauge

Material Type: Select a gauge suitable for the materials you need to measure.

Accuracy Requirements: Different industries demand varying degrees of precision.

Measurement Range: Ensure the gauge covers the thickness range needed.

Ease of Use Portability: Consider handheld vs. benchtop models based on operational needs.

Data Storage Connectivity: Advanced gauges offer digital storage and connectivity for better analysis.

Conclusion

A Wall Thickness Gauge is an indispensable tool for ensuring the quality, safety, and longevity of industrial components. Whether you’re in manufacturing, construction, or engineering, investing in the right gauge enhances precision and compliance with regulatory standards. At Labzenix.com, we provide top-tier wall thickness gauges to meet the diverse needs of modern industries. Contact us today to find the best solution for your applications!