Unlock the Secret to a Smoother Ride: Transform Your Truck with Air Suspension Kits!

As a truck owner, you know how vital it is to have a vehicle that not only performs well but also provides a comfortable ride. One of the most effective ways to enhance your truck's performance and ride quality is through the installation of air suspension kits. These innovative systems address common suspension issues that many truck owners face, such as rough rides, inconsistent handling, and trouble with load leveling. Air suspension kits can effectively mitigate these problems, offering a solution that allows your truck to handle varying loads with ease and grace. Whether you're hauling heavy equipment or just navigating bumpy roads, understanding the value of air suspension kits is essential for every truck enthusiast.

Understanding Air Suspension Kits

Air suspension kits replace traditional coil or leaf spring systems with air-filled bags that can be inflated or deflated to adjust the vehicle's ride height and firmness. These kits consist of several key components, including air springs, an air compressor, air lines, and a control system. Unlike conventional suspension systems that rely on metal springs, air suspension allows for a smoother ride by providing adjustable cushioning based on the load and road conditions. This adaptability is particularly beneficial for trucks, which often encounter varied terrains and loads. By using air instead of rigid materials, air suspension systems can absorb shocks more effectively, leading to improved vehicle stability and comfort.

Benefits of Installing Air Suspension Kits

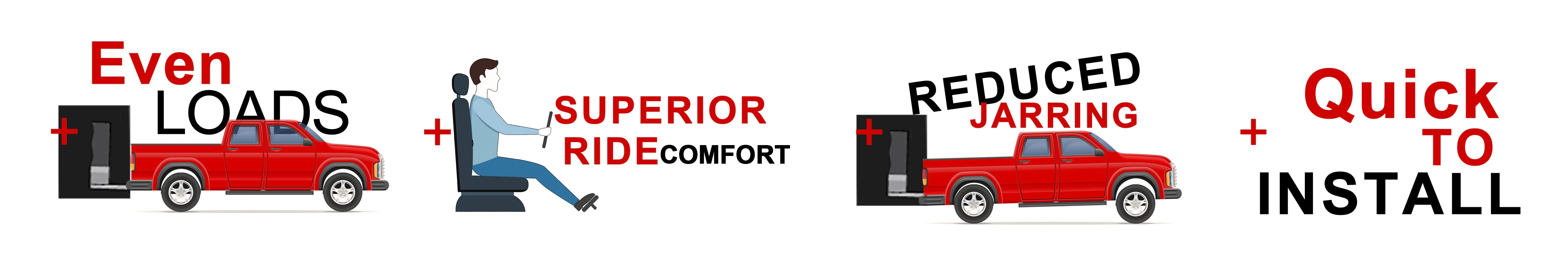

The advantages of installing air suspension kits on your truck are numerous. One of the most notable benefits is the improved ride comfort; air suspension systems can adjust to the weight of the load, ensuring a smooth journey regardless of the circumstances. Additionally, these kits significantly enhance load leveling, allowing for even distribution of weight across the axles, which can be a game-changer when towing trailers or carrying heavy payloads. Furthermore, air suspension improves overall vehicle handling, providing more control during turns and on uneven surfaces. Personal experiences from friends who have upgraded to air suspension reveal that the difference in ride quality is not just noticeable—it's transformative, allowing them to enjoy long drives without fatigue.

Factors to Consider When Purchasing Air Suspension Kits

When considering the purchase of air suspension kits, several key factors must be taken into account to ensure you make the right choice for your truck. First and foremost, vehicle compatibility is crucial; not all kits will fit every truck model. It's essential to select a kit designed specifically for your vehicle type. Additionally, evaluate the weight capacity of the air suspension system to ensure it can handle your typical loads. Installation requirements should also be considered; some kits may require professional installation, while others can be a DIY project if you have mechanical skills. Lastly, consider maintenance needs—while air suspension systems are generally low-maintenance, regular checks and understanding the system are vital for long-term performance.

Installation Process of Air Suspension Kits

The installation process for air suspension kits can vary depending on the complexity of the system and your mechanical expertise. Generally, the process involves lifting the truck, removing the existing suspension components, and replacing them with the air suspension system. Essential tools include wrenches, screwdrivers, and possibly a compressor for inflating the air bags. While some truck owners find installation manageable, others may encounter challenges such as fitting issues or needing additional parts. For those less experienced, seeking professional installation might be a wise choice, as it ensures the system is set up correctly and can save you from potential headaches down the road.

Maintenance Tips for Air Suspension Kits

Maintaining your air suspension system is crucial for optimal performance and longevity. Regular checks of the air bags for leaks, visual inspections of the lines, and monitoring the inflation levels are important practices. Keeping the air compressor and control system in good working order will also minimize issues. If you notice any unusual handling or ride quality, troubleshooting promptly can prevent further complications. Simple steps like keeping the system clean and ensuring the air bags are appropriately inflated based on load will help extend the life of your air suspension kit.

Enhancing Your Truck Experience

In summary, air suspension kits offer truck owners a remarkable way to enhance ride quality, improve handling, and manage heavy loads effectively. By understanding the benefits and considerations of these systems, you can make an informed decision that will lead to a smoother ride. Investing in a quality air suspension kit is not merely about comfort; it's about ensuring the long-term performance and reliability of your truck. So, take the plunge and explore the world of air suspension kits—your truck (and your back) will thank you!